In today’s competitive industrial landscape, conveyor belt automation has evolved from a supportive mechanism to a core component of smart manufacturing. Production units across automotive, packaging, heavy engineering, pharma, and food processing are rapidly adopting automated conveyor systems to improve speed, minimize manual work, and drive higher production output with precision.

This shift aligns perfectly with the principles of Industry 4.0, where data-driven operations and integrated automation become the foundation of operational excellence.

Why Conveyor Belt Automation Is Becoming a Standard

Manual material movement slows down operations, creates inefficiencies, and increases risk. With conveyor belt automation, factories achieve:

Conveyor belt automation is now a strategic investment, not just an equipment upgrade.

| Key Benefit | Impact on Operations |

| Faster production speed | Up to 40% increase in output |

| Lower manual labor dependency | Predictable workflow & fewer errors |

| Accurate tracking of material flow | Reduced wastage & delays |

| Safer working environment | Lower chances of workplace injury |

| Real-time monitoring via sensors | Data-driven operational control |

| Integration with IoT & PLC | Smart factory capability |

Industry 4.0 + Conveyor Automation = Competitive Advantage

Factories today need more than machinery — they need connected, intelligent production environments. Conveyor belt automation helps companies:

✔ Scale production

✔ Optimize resource usage

✔ Reduce overtime cost

✔ Maintain consistency

✔ Create a “zero-interruption” operational model

That’s why many manufacturers now see conveyor automation as a profit-center, not a cost-

center.

Core Components of an Automated Conveyor System

A modern conveyor belt automation setup includes:

| Component | Function |

| Sensors & detectors | Track load, movement, & timing |

| PLC control systems | Automate workflow & commands |

| Motors & drives | Dynamically control belt speed |

| SCADA / HMI dashboards | Enable visual monitoring |

| Robotic pick & place arms | Integrate for advanced handling |

| IoT connectivity | Enables predictive maintenance |

When integrated correctly — these components work together as a synchronized production ecosystem.

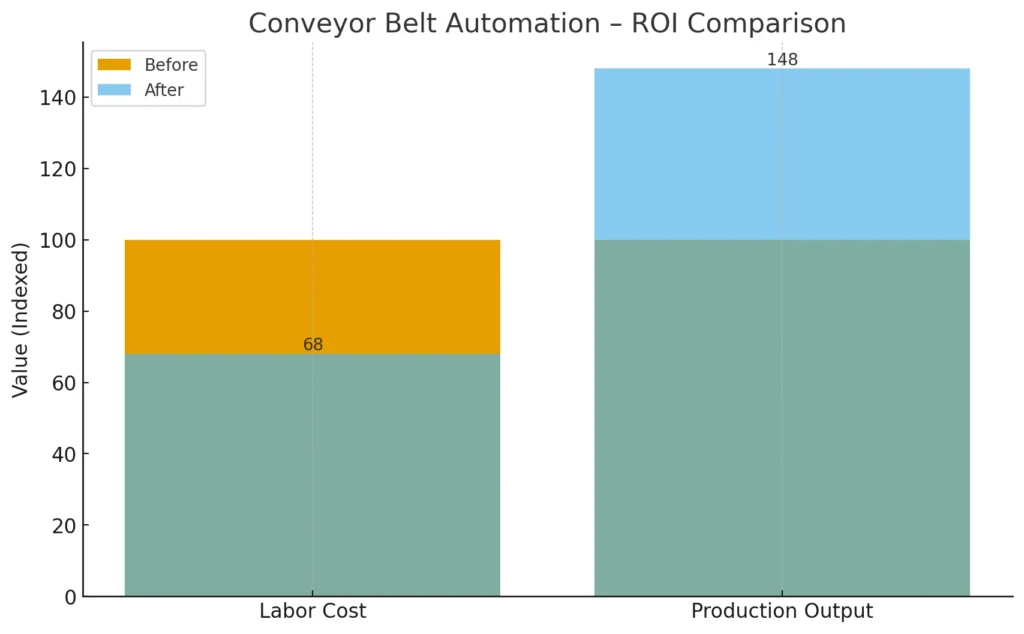

Proven ROI – Real Implementation Results

A mid-sized manufacturing company implemented conveyor belt automation integrated with PLC and smart sensors. Within 9 months, the results were:

This shows that conveyor belt automation is not only about automation — it is about operational transformation.

Planning Conveyor Belt Automation – Things to Consider

Before choosing a system, every factory must evaluate:

| Factor | Why It Matters |

| Load capacity | Affects motor & belt type |

| Speed control requirements | Determines drive system |

| Space layout of plant | Impacts design & simulation |

| Material handling type | Pharma vs heavy industry |

| Safety protocols | Industrial compliance standards |

| Integration capability | PLC, robotics, IoT, ERP |

A custom engineering assessment is essential for ROI success.

Industries Using Conveyor Belt Automation

✔ Automotive & EV Component Assembly

✔ Warehouse & Logistics

✔ Food & Beverage Packaging

✔ Electrical & Electronics Manufacturing

✔ Heavy Engineering & Metal Fabrication

✔ Pharmaceutical Material Handling

Each industry adapts the technology differently — via layout engineering, conveyor type selection, and automation integration.

Enhanced Safety and Reduced Operational Risks

Conveyor belt automation not only improves efficiency but also significantly enhances workplace safety. By minimizing human interaction with heavy machinery, the risk of accidents and injuries is drastically reduced. Automated sensors and emergency stop systems ensure that the production line operates within safe parameters at all times. Additionally, predictive maintenance alerts help prevent unexpected breakdowns, protecting both personnel and equipment. Investing in automated conveyor systems creates a safer, more controlled manufacturing environment while maintaining uninterrupted workflow.

Future Trends in Conveyor Belt Automation

The next phase of automation will go beyond material movement. Emerging trends include:

✔AI-enabled belt performance optimization

✔Self-learning conveyor systems

✔Advanced robotic integration

✔Real-time digital twins

✔Energy-efficient belt systems

✔Augmented maintenance alerts

These technologies will drive continuous improvement in OEE (Overall Equipment Efficiency).

Exploring Conveyor Belt Automation for Your Factory?

If you’re planning to upgrade your existing manufacturing line or build a new automation layout, a correctly engineered conveyor system can deliver measurable ROI in months – not years.

Learn more about automation-driven conveyor solutions:

Industrial Automation Experts – Sunbio IT Solutions

Contact – https://sunbioit.com/Contact.html

Conclusion

Conveyor belt automation is not merely replacing manual work — it is redefining the industrial production model.

Factories that adopt it today will position themselves as future-ready, agile, and cost-efficient leaders in their industry segment.

The shift is no longer optional — it’s strategic.